- Home page

- MAMI

- Products home

- QTube videos

- Qprojects

OMNIS ISTE

Sed ut perspiciatis

Omnis iste natus error sit

Omnis iste natus error sit

Sed ut perspiciatis

Omnis iste natus error sit

Omnis iste natus error sit

MAMI

Sed ut perspiciatis

Omnis iste natus error sit

Omnis iste natus error sit

Mass production Administration by Multiple Inquiries

Smooth scrolling and rolling planning features with great graphical visibility of history, actual and planned future of known bottlenecks of production in various time scales.

Tools to carry out time critical production planning schedule released over company's interest groups for all over refreshed and valid, all the time, in real time.

Tools to carry out time critical production planning schedule released over company's interest groups for all over refreshed and valid, all the time, in real time.

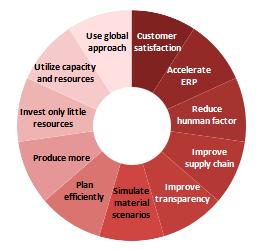

What you can do with MAMI?

Mass production Administration by Multiple Inquiries

Increase the customer satisfaction by delivering them as promised (sales availability management)

Accelerate your ERP system and utilize the data properly

Reduce significance of human factor - increase Supply Chain efficiency and reliability

Take your S&OP to whole new level

Create integrated business process across the functions/organizations and extend it to include external suppliers and LSP's

Create better visibility and transparency throughout the whole organization on all levels

Easily run material simulations for different scenarios

Ensure that demand and supply meets at the right time and at the right place

Achieve greater productivity without a huge investment with proper multi-level production planning utility

Utilize your capacity more efficiently

Avoid missed orders - Make higher profits

Dynamically change plans as needed - Fluctuation in customer demand or supplier capability

Have your order book status at glance - even across to multiple manufacturing plants globally

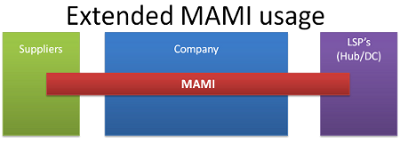

MAMI usage

Mass production Administration by Multiple Inquiries

- Business case: Manufacturing and supply chain management

- Who benefits the most: Large companies running business on international scale having production plants and Hubs/DC's located on several continents worldwide

- Supported business models: MTO, MTS, STO (hub)

- Typical user groups: Sales and marketing, Production planning and

management, Logistics, Purchasing, Business management

MAMI usage can be extended to the partners to get even more out of it

Better visibility to your supply chain

Real-time information of order statuses

Faster information sharing and less time to adapt to changes

MAMI usage in business areas:

On Corporate level: Availability management and global planning

In Sales: Manage your sales orders in every part of your process: from availability check to order confirmation and re-scheduling

In Production: Plan and schedule your manufacturing execution on detailed level and manage your production capacity

In Material Management: Simulate your material behaviour with different scenarios and create detailed purchase plans with real-time MRP/MPS utility

In Management: Base your decisions on accurate and real-time data and plans

MAMI Features and functions

Mass production Administration by Multiple Inquiries

Sales & availability management

- Real-time graphical view of material and capacity shortages

- ATP calculation through whole product hierarchy

- Global planning

Capacity management

- Concurrent capacity usage versus capacity in graphical mode

- Drag & drop planning

Material management

- Real-time MRP calculation

- Automaticly generated purchase plans

- Calculation of free and used forecast

Product life cycle management

- Version change planning based on real-time stock levels

Supplier management

- Small and mid-sized supplier co-operation within same user interface

MAMI features:

- Genuine graphic interface

- Optimized data warehouse

- Interactive flow diagrams

- Real-time synchronization

- Mobile version

- Scalable performance

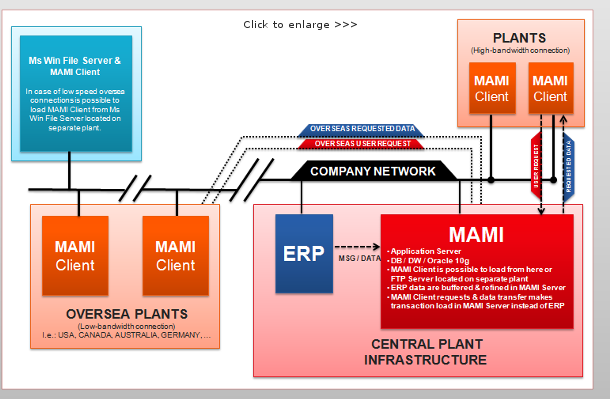

- Separate DB and server system, causing less load on core ERP system

Techniques and technology behind

Mass production Administration by Multiple Inquiries

What is the thechnology behind MAMI and what are the main characteristics of it?

Real-time fully automated system

MRP run can run anytime you need it, creating no load in your ERP system

Integrates to any ERP system

User friendly graphical user interface

Multiple calendars can be used inside one plant. Scheduling plan can be done in time-scaled axis as well as on hour/ shift /day /week /month level.

No separate BW needed

Very scalable environment

Very advanced user authentication

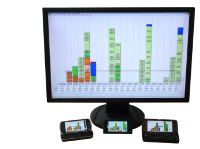

Complementary Mobile version - M4MAMI

Mass production Administration by Multiple Inquiries

Decision support information available anywhere in real-time

Secure connection either through WLAN or mobile internet

Data synchronization and local database allows you to work even without network connection

Decision support information for sales, DSP, production and acquire operations available anytime and anywhere

Comparisons and calculations between orders, forecasts, plants, capacities, ... in graphical user interface

No more need of carrying large amount of paper sheets or using laptops

... power of MAMI-solution,

in and out of office at your fingertips ...

in and out of office at your fingertips ...

Finnish

Finnish

English

English